The company undertakes the construction of LV and MV underground networks, interconnection of either wind turbines or photovoltaics inside the projects as well as external interconnection lines with the respective substation of the project or the system. The underground network can include copper or aluminum cables of various cross sections, up to 1000mm2, copper conductors for grounding and fiber optic cables. In addition, our technicians can perform any termination, connection or the installation of all the necessary MV underground cable joints.

For the construction of underground networks, our company has modern machinery, equipment and special “cabled” crane trucks, all terrain, equipped with hydraulic rollers. When required by the nature of the project, our company can build networks, even in very difficult topographies, using specially designed tracked machines, suitable for cable installation.

Our experienced technicians undertake the supply and installation of electrical equipment and are able to carry out installations of switchgear LV and MV in outdoor substations, in substation buildings and inside the wind turbines. Our engineers are high qualified to carry out not only the construction of any E / M project but furthermore, its maintenance and repair. The company undertakes the supply and installation of M / S and the switchgears of low and medium voltage, generating pairs, Uninterruptible Power Supply (UPS) systems, grounding systems and performs regular maintenance substations of wind farms, photovoltaics and public buildings.

Our company, with the use of the most advanced equipment, ensures both the accurate diagnosis of the critical points and the troubleshooting of the electrical installations, as well as the immediate restoration of any electrical fault. Furthermore, with the aim of minimizing the costs of our customers, our company promotes the preventive inspection of electrical installations, with annual contracts of measurements, maintenance and repair of faults, in order to ensure the smooth and proper operation of electrical installations. Specifically it provides:

- Electrical Inspection and Safety : Periodic inspection and maintenance of electrical installations ensure both the safety of the personnel and the protection of appliances, in addition we prevent faults that are always costly.

- Cable Fault PinPointing : Localization of cable fault is the most important task performed on power distribution lines. The quick response and the accuracy of this work is especially important because cable faults cause power outages, which cost both the consumer and the provider. The advanced equipment of the company offers methods of localization and the accuracy of point detection, thus achieving fast and accurate detection of faults and its immediate restoration.

- Cable Inspection and Testing : Our company conducts cable tests to eliminate the occurrence of failure, by checking the quality of the cables both during receipt and repair, but also by diagnosing the possibility of damage in future use.

The cable terminations are performed in order to check their condition, to minimize the occurrence of damage and to check whether they can withstand future use. The proprietary equipment offers great possibilities for testing and testing the cables provided by national and international standards.

The tests that can be performed are:

- Continuous Voltage Control.

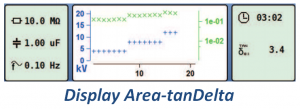

- Dissipation Factor/TanD tests

- Control with alternating voltage 0.1Hz- Very Low Frequency (VLF).

- Control by the method of partial discharges – Partial Discharge (PD).

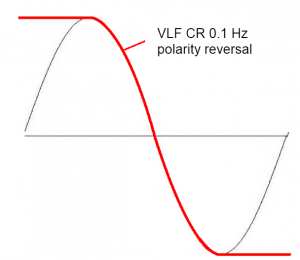

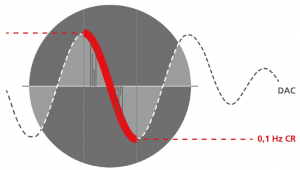

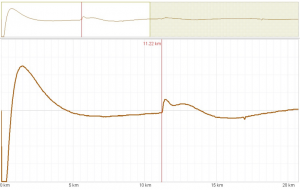

The company’s advanced equipment offers the following voltage waveforms for the tests: the VLF 0.1 Hz and the Damped AC voltage, which operate according to the principle of 50 Hz (Cosine Rectangular -CR). Damped AC (DAC) has been shown to be the appropriate voltage waveform for the non-destructive control of partial discharges – PD. In addition, it offers the sine waveform 0.1 Hz for the VLF test. Finally, tests are performed using the DC voltage and the tand test.

Our company owns portable instruments that have innovative modern technologies which offer reliable solutions that lead to maximum efficiency. The accurate localization of the LV. and M.V underground network’s fault, is achieved with the complexity of the localization methods and the accuracy of the point localization- pin point

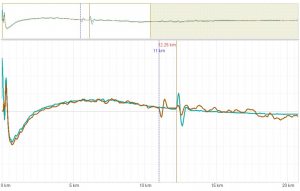

- Pre localization Cable Faults : Our Company owns equipment which allows to localize faults by measuring reflection. A high frequency pulse diffuses into the cable and as the impedance of the cable changes within it, it affects the reflection of the pulse. Pulse reflections are caused by faults, connectors, cable type change or other causes of impedance change. The amplitude of the reflection depends on the degree of change of the impedance. The equipment enables the following three debugging tests to be performed:

- Pre localization fault with the reflection method – ARM ( Arc Reflection Method )

This method is for the pre-location of high-resistance cable faults. Use arc reflection measurements combined with high capacitance surge generator and pinpointing devices for underground cables locating will find faults in less time and with less risk of damaging cable method of fault pre-locating combines the use of TDR and surge generator (Thumper). This method allows the detection of high resistance faults, which appear from the operating voltage and above, by measuring the reflection without changing or aggravating the fault. The reflectometer (Teleflex) visualizes the position of the fault.

- The decay method is used to pre-location a high resistance cable faults with a high ignition of voltage in chargeable cables. To this end, the cable is charged with a dc voltage until it exceeds the faults breakdown voltage. The energy stored in the cable capacitance discharges through the fault and generates a travelling wave, which is recorded and displayed by the TDR as an attenuated oscillation. The period of this oscillation can be used to determine the actual fault distance.

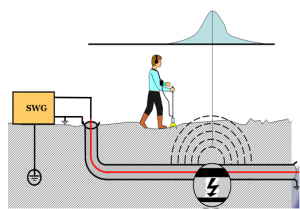

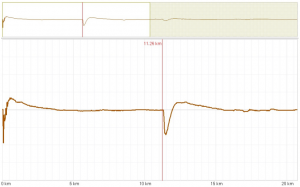

- Current Decoupling Method (ICE) : Pre-location using the current decoupling method (ICE) has established itself, particularly with regard to faults in the lower kOhm range and for extremely large fault distances, in which the ARM method often fails to achieve any results. As with the ARM method, a capacitive discharge of the surge wave generator ignites the fault and causes it to a flash over. Consequently, an attenuated transient wave moves back and forth between the fault and the surge generator. Decoupling the current induces the Teleflex SX into displaying an oscillation, which has a period equivalent to a single fault distance.After the pre-location test, pinpoint test was applied to determine the exact point of the cable fault.For this purpose, a surge wave receiver used. A surge generator feeds surge voltage pulses into the faulty cable. A pickup in the receiver detects the magnetic field produced by the current impulse and also displays its magnitude on a bar graph display every time the thumper discharges

- Pinpoint Test with surge generator & microphone : After the pre-location test, pinpoint test was applied to determine the exact point of the cable fault. For this purpose, a surge wave receiver used. A surge generator feeds surge voltage pulses into the faulty cable. A pickup in the receiver detects the magnetic field produced by the current impulse and also displays its magnitude on a bar graph display every time the thumper discharges.